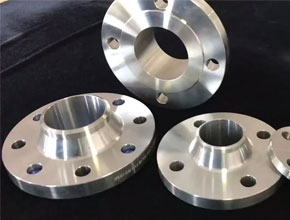

Ample Alloys is a globally accepted Manufacturers and Exporter of ASTM B564 Alloy 718 Weld Neck Flange, Werkstoff Nr 2.4668 Slip On Flange, UNS N07718 Threaded Flange, Class 150 Inconel 718 Orifice Flanges, Inconel 718 Spectacle Blind Flange, Inconel 718 Blind Flange, Inconel 718 RTJ Flange, Inconel 718 Ring Spacer Flange.

Table of Content

- ASTM B564 Inconel 718 Slip On Flange Specifications

- UNS N07718 Orifice Flange Chemical Composition

- WERKSTOFF NR. 2.4668 Weld Neck Flange Mechanical Properties

- ASME SB564 Alloy 718 Threaded Flanges Equivalent Material Grades

- Inconel 718 Industrial Flange Types

- Inconel 718 Similar Products

- Inconel 718 Blind Flange Applications

- In Stock Inconel Alloy Flanges Grades

- ½” – 24” Flanges Weight Chart

- ANSI B16.5 Flanges – Dimensional Tolerances

- Industrial Flanges Dimensions ANSI B16.5

Mumbai, India-based Suppliers of Inconel 718 Lap Joint Flange. Flange Dimensions in MM, Specification, Standards, Weight, Types, Prices, Schedule, Drawing, Application, Thickness, Temperature Limitation, Material, Pressure Rating, Advantages, Bolt Chart. Get Best Price List of ASTM B564 Inconel Alloy 718 Flanges in Qatar, Kuwait, Latin America, Italy, Australia, Japan, USA, Canada, Dubai, and UK.

Inconel 718 Flanges Specifications

- Specifications: ASTM B564 / ASME SB564

- Flange Size Range: NPS 1⁄₂” To NPS 48”

- Pressure Rating: Class 150(lb), Class 300(lb), Class 600(lb), Class 900(lb), Class 1500(lb), Class 2500(lb)

- Standards: ANSI B16.5, ANSI B16.47 Series A & B, ASME 16.36, MSS SP44, ASA, API-605, AWWA, ISO-70051, JIS B2220, EN1092, BS 10

- Class: PN6, PN10, PN16, PN25, PN40, PN64 etc.

- Grades: Alloy 718 / 2.4668 / UNS N07718

- International Specifications: WERKSTOFF NR. / UNS / JIS / BS / GOST / AFNOR / DIN / EN

- Shapes and Types: RTJ-Ring Type Joint, LMF-Large Male-Female, FF-Flat Face, Small Tongue, SMF-Small Male-Female, RF-Raised Face, Large Tongue & Groove, Groove, LJF-Lap-Joint Face

- Production Technique: Forged/ Heat treated and machined

- Test Certificates: Raw Materials Certificate, EN 10204/3.1B, Third Party Inspection Report, 100% Radiography Test Report

Inconel 718 Flanges Chemical Composition:

| Grade | Inconel 718 |

|---|---|

| C | 0.08 max |

| Mn | 0.35 max |

| Si | 0.35 max |

| Fe | Balance |

| S | 0.015 max |

| Cr | 17.0 – 21.0 |

| Cu | 0.30 max |

| Ni | 50.0 – 55.0 |

Inconel 718 Flanges Mechanical Properties:

| Element | Inconel 718 |

|---|---|

| Density | 8.2 g/cm3 |

| Melting Point | 1350 °C (2460 °F) |

| Tensile Strength | Psi – 1,35,000 , MPa – 930 |

| Yield Strength (0.2%Offset) | Psi – 75,000 , MPa – 482 |

| Elongation | 45 % |

Inconel 718 Flanges Equivalent Material Grades:

| WERKSTOFF NR. | UNS |

|---|---|

| N07718 | 2.4668 |

Inconel 718 Flanges Types

- Inconel 718 Slip on Flanges

- Inconel 718 Weld Neck Flanges

- Inconel 718 Orifice Flanges

- Inconel 718 Spectacle Blind Flanges

- Inconel 718 Paddle Blind Flanges

- Inconel 718 Ring Spacer Flanges

- Inconel 718 Ring Type Joint Flanges

- Inconel 718 Threaded Flanges

- Inconel 718 Lap Joint Flanges

- Inconel 718 Long Weld Neck Flanges

- Inconel 718 Backing Ring Flanges

- Inconel 718 Nipoflange

- Inconel 718 Blind Flanges

- Inconel 718 Socket Weld Flanges

- Inconel 718 Weldoflange

- Inconel 718 Flangeolet

- Inconel 718 Raised Face Flanges

- Inconel 718 Forged Flange

- Inconel 718 ANSI Plate Flanges

- Inconel 718 Tongue and Groove Flanges

- Inconel 718 Male & Female Flanges

- Inconel 718 BS 4504 Flanges

- Inconel 718 EN 1092-1 Flanges

- Inconel 718 High Hub Blind Flanges

- Inconel 718 Reducing Flanges

- Inconel 718 BS 10 Flanges

- Inconel 718 DIN Flanges

- Inconel 718 Square Flanges

- Inconel 718 Expander Flanges

- Inconel 718 MSS SP-44 Flanges

- Inconel 718 Korean Flanges

- Inconel 718 EN 1092-1 Type 01 Flanges

- Inconel 718 EN 1092-1 Type 02 Flanges

- Inconel 718 EN 1092-1 Type 05 Flanges

- Inconel 718 AS/ANZ 4331.1 Flanges

- Inconel 718 Norwegian Flanges

- Inconel 718 ISO Flanges

- Inconel 718 UNI Flanges

- Inconel 718 EN 1092-1 Type 11 Flanges

- Inconel 718 BS4504 Blind Flanges

- Inconel 718 EN 1092-1 Type 13 Flanges

- Inconel 718 BS4504 Threaded Flanges

- Inconel 718 BS4504 Plate Flanges

- Inconel 718 UNI Blind Flanges

- Inconel 718 UNI Loose Flanges

- Inconel 718 BS4504 Weld Neck Flanges

- Inconel 718 UNI Welding Neck Flanges

- Inconel 718 JIS B2220 Flanges

- Inconel 718 API Flanges

- Inconel 718 UNI Plate Flanges

- Inconel 718 UNI Threaded Flanges

- Inconel 718 GOST Flanges

- Inconel 718 AWWA Flanges

- Inconel 718 Bleed Ring

- Inconel 718 Drip Ring

- Inconel 718 Vent Ring

Inconel Alloy 718 Similar Products

Inconel 718 Flanges Applications

Alloy 718 Flange is used to connect pipes, valves, pumps, and other equipment to form a piping system. Inconel Grade 718 Flanges also provide easy access for cleaning, inspection, or modification. It is usually welded or screwed. Flanged joints are made by bolting together two flanges with a gasket between them to provide a seal. Following are list of application industries where flanges are frequently used:

- Gas Processing

- Chemical Processing

- Petrochemical Facilities

- Cryogenic Plants

- Paper Production

- Waste Treatment Facilities

- Nuclear Power Plants

- Breweries

The wide range of applications demonstrates the robustness of UNS N07718 Flanges and how much this particular type of fitting is relied upon. We at Ample Alloys provide all necessary Material Testing Reports and Documentation and provide packaging of the products i.e. Grade 718 Industrial Flanges as per clients’ requirements or as per industry standards to keep products damage free during transit.