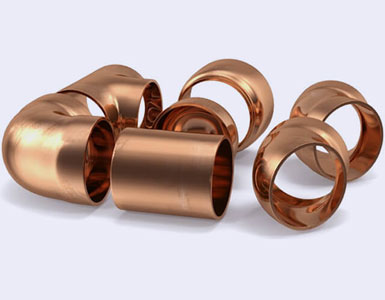

Ample Alloys is a globally accepted Manufacturers and Exporter of ASTM B467 Cu-Ni 90/10 Socket Weld Couplings, UNS C70600 SW Unions, Werkstoff Nr 2.0872 SW Tee, Class 150 Cupro Nickel 90/10 SW Elbow, 90/10 Cu-Ni SW End Cap, Cu-Ni 90/10 SW Cross, Grade 90/10 SW Nipple, CuNi 90/10 SW Boss, Cupro Nickel 90/10 SW Adapter, SW Reducers.

Table of Content

- ASTM B467 Copper Nickel 90/10 Socket Weld Fittings Specifications

- UNS C70600 Socket Weld Fittings Chemical Composition

- WERKSTOFF NR. 2.0872 Socket Weld Fittings Mechanical Properties

- ASME SB467 Cu-Ni 90/10 Socket Weld Fittings Equivalent Material Grades

- Copper Nickel 90/10 Socket Weld Forged Fittings Types

- Copper Nickel 90/10 Similar Products

- Copper Nickel 90/10 Socket Weld Forged Fittings Applications

- In Stock Copper Nickel Socket Weld Forged Fittings Grades

- Forged Fittings Weight Chart

- Forged Socket Weld Fittings Dimensions ASME B16.11

Mumbai, India-based Suppliers of Copper Nickel 90/10 Socket Weld 90 Degree Elbow. Socket Weld Forged Fittings Types, Dimensions Chart, Weight, Wall Thickness, Pressure Rating, ASME Standard, Material, Catalogue, Class, Size Chart, PDF, 3D Model, HS Code. Get the Best Price List of ASTM B467 Cu-Ni 90/10 Socket Weld Full Coupling in Australia, USA, Kuwait, Italy, Japan, Qatar, UK, Canada, Latin America, and Dubai.

Copper Nickel 90/10 SW Fittings Specifications

- Size Range: 1/8″~ 4″ (Dn6 ~ Dn100)

- Specifications: ASTM B467 / ASME SB467

- Pressure Class: 3000 LBS, 6000 LBS, 9000 LBS

- Standards: ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

- Value Added Services: Epoxy & Fbe Coating, Hot Dipped Galvanizing, Sand Blasting, Electro Polish, Threading, Soldering

- Grades: Cu-Ni 90/10 / 2.0872 / UNS C70600

- DIN: Din 2617, Din 2605, Din 2616, Din 2615, Din 28011

- EN: En 10253-2, En 10253-1

- International Specifications: WERKSTOFF NR. / UNS / JIS / BS / GOST / AFNOR / DIN / EN

- Price: Contact info@amplealloys.com

Copper Nickel 90/10 Socket Weld Fittings Equivalent Material Grades:

| WERKSTOFF NR. | UNS |

|---|---|

| 2.0872 | C70600 |

Cu-Ni 90 / 10 Socket Weld Fittings is being designed in accordance with national and international raw material quality standards. In this alloy, the neck, or focal point, exerts pressures from the bottom of the focal point to the wall breadth at the butt weld, significantly strengthening the alloy. Meanwhile, they are typically used in high-pressure systems and are suitable for both hot and cold temperatures. It is manufactured at our facility for companies in various industries such as shipbuilding, petrochemical plants, power generation, and so on.

Ample Alloys is a known exporter and stockist of Cupro nickel 90 / 10 Socket Weld Fittings, which is ideal for high-stress environments. At greater temperatures, they also have higher creep, stress-to-rupture, and tensile strength. They have been employed in the handling of numerous chemicals used by chemical process industries due to their exceptional corrosion resistance. It is usual for this steel to achieve the mechanical qualities of straight grade while keeping a low carbon content with the regulated addition of nitrogen.

Copper Nickel 90/10 Socket Weld Fittings Types

- Copper Nickel 90/10 Socket Weld Union

- Copper Nickel 90/10 Socket Weld End Cap

- Copper Nickel 90/10 Socket Weld Lateral Tee

- Copper Nickel 90/10 Socket Weld Adapters

- Copper Nickel 90/10 Socket Weld Cross

- Copper Nickel 90/10 Socket Weld Branch Outlet

- Copper Nickel 90/10 Socket Weld Reducing Tee

- Copper Nickel 90/10 Socket Weld Half Coupling

- Copper Nickel 90/10 Socket Weld Nipple

- Copper Nickel 90/10 Socket Weld Reducers

- Cu-Ni 90/10 Socket Weld 90 Degree Elbow

- Copper Nickel 90/10 Socket Weld Reducer Insert

- Copper Nickel 90/10 Socket Weld Tee / Equal Tee

- Copper Nickel 90/10 Socket Weld Full Coupling

- Copper Nickel 90/10 Socket Weld Boss

- Cu-Ni 90/10 Socket Weld 45 Degree Elbow

- Cu-Ni 90/10 Socket Weld 90° Elbow Outlet

- Copper Nickel 90/10 Socket Weld Lateral Outlet

Cu-Ni 90/10 Similar Products

Copper Nickel 90/10 Socket Weld Fittings Applications

Cu-Ni 90/10 Forged Socket Welding (SW) fittings are mainly used to permanently join pipes that are inserted into a recess in the fitting, flange, or valve. Once correctly inserted, fillet-type sealing welds are applied to join the pipe to the fitting. It is commonly known as SW pipe fittings, with SW elbows, SW couplings, and SW tees being examples of different types.

CUNI 90/10 – Copper Nickel offers excellent corrosion resistance, especially in marine saltwater environments. The most popular specifications in Europe and America are C70600, CN102, and CW352. The 90/10 alloys are widely used as they are inexpensive. 90/10 cupronickel is a 90% copper, 10% nickel alloy that also contains small but important additions of iron and manganese to enhance overall strength and corrosion resistance.

Following are list of applications & industries:

- Off-Shore Oil Drilling Companies

- Sea Water Equipment

- Power Generation

- Chemical Equipment

- Pharmaceutical Equipment

- Gas Processing

- Pharmaceuticals

- Pulp and Paper Industry

- Heat Exchangers

- Condensers

- Petrochemicals

- Specialty Chemicals

ASME B16.11 Cu-Ni 90/10 Socket Weld Pipe Fittings are available in three pressure ratings Class 3000, Class 6000, and Class 9000. We at Ample Alloys provide all necessary Material Testing Reports and Documentation and provide packaging of the products i.e. Grade 90/10 SW Fittings as per clients’ requirements or as per industry standards to keep products damaged free during transit.

Types of Socket Weld Fittings by Class and Size:

| Description | Class Designation | ||

|---|---|---|---|

| 3000 | 6000 | 9000 | |

| Elbows 45 and 90 degrees, Tees, Crosses, Couplings, Half-Couplings, End or Pipe Caps |

1/2 – 4 | 1/2 – 2 | 1/2 – 2 |

| 1/2 – 4 | 1/2 – 2 | 1/2 – 2 | |

| 1/2 – 4 | 1/2 – 2 | 1/2 – 2 | |

| Pipe Size by Wall Thickness |

SCH 80 / XS | SCH 160 | XXS |